Drive sustainability within your supply chain

Problem Overview

It has become imperative for companies to examine each stage of their supply chain and consider efficiencies that could be implemented. A study demonstrates that 80-90% of the world’s goods are transported by sea. Each year, container ships spew about 1 billion metric tons of carbon dioxide into the air — about 3% of all greenhouse gas emissions.

“According to McKinsey, the typical consumer company’s supply chain accounts for more than 80% of greenhouse gas emissions and more than 90% of the impact on air, land, water, biodiversity and geological resources.”

The Challenge

To identify highest sources of carbon emissions and monitor sustainability in the entire supply chain

Recent events about the problem

Including the huge loads of greenhouse gasses and carbon emissions that are released by supply chains, consumers are also getting aware of the unethical practices that exist in many supply chains – like child labour, forced labour, and gender discrimination. A Deloitte research revealed that 65% of respondents expect CEOs to do more to make progress on societal issues, including reducing carbon emissions, tackling air pollution, and making business supply chains more sustainable.

Why is this a serious problem

Consumers advocate sustainability

- According to the Carbon Trust, 45% of shoppers would be prepared to stop buying their favorite brands if

they refused to commit to measuring their product carbon footprint. - As per an Oliver Wyman survey, more than 7 out of 10 respondents of younger generations were more likely to say that a company’s emissions commitments would influence their willingness to buy goods from them.

- Deloitte’s research shows that 23% of consumers say they will switch to buying products from an organization that shares their values on environmental issues and 42% have already changed their consumption habits because of their stance on the environment.

Corporate bottom lines are taking a hit

- McKinsey found that upward of 70% of consumers would pay an additional 5% for a green product than for a comparable non-green alternative.

- According to McKinsey, those products that were marketed as sustainable have been growing 5 to 6 times faster than the average market.

- The World Economic Forum shows that sustainable sourcing practices in supply chains can reduce costs by up to 16%.

Serious lack in supply chain visibility

- In a recent survey by The Sustainability Consortium (TSC), more than 50% of the 1,700 respondents reported being unable to determine sustainability issues in their supply chains.

- A report from the Economist Intelligence Unit (EIU) commissioned by The Association for Supply Chain Management (ASCM) claims that more than half of companies lack end-to-end visibility in their supply chains. Consumers advocate sustainability Corporate bottom lines are taking a hit Serious lack in supply chain visibility.

The Cost of inaction

Loss of customers

Most of the consumers that participated in the Oliver Wyman Forum believe that corporations should make commitments to reduce their carbon footprints and become net-zero emitters, and many of them claim that those commitments will influence where they buy goods and services. Another Deloitte research of 2022 indicated that 40% of consumers shifted to brands that had environmentally sustainable practices/ values, a 6% rise compared to the previous year.

As customers (both businesses and consumers) are seeing the real-world results of climate change on newsfeeds and streaming channels daily, they are quickly shifting loyalties to companies that demonstrate significant, permanent steps toward a sustainable future customers.

Higher Cost

“Greening” your business might take an initial investment, but, over time, corporations have drastically reduced their costs by prioritizing sustainability. A McKinsey survey on the of sustainability revealed that 33% of businesses were integrating sustainable practices specifically to improve operational efficiency and cut costs — resulting in a 19% increase from the previous year.

Bad Reputation

Having a climate friendly and sustainability in the supply chain not only enhances a corporation’s brand but also protects it from garnering a bad reputation.

In today’s digital era and age of easy access to information and even easier dissemination of said information, one claim of non-compliant practice in any part of a corporation’s supply chain could mean the death sentence for their company, or if not that, a massive hit to their bottom lines and revenues. A new international study by Unilever reveals that a third of consumers (33%) are now choosing to buy from brands they believe are doing social or environmental good.

Consumer’s view sustainability as a plus, and corporations with green values are seen to be superior to the ones that don’t advocate a climate friendly mode of operation. Going green depicts an organization’s priority to something of more emphasis than money.

Products marketed as “sustainable” grew 5-6X faster than regular products.

In the US 75% of 18-34 year old employees expect their employers to take a stand on climate change

Solution

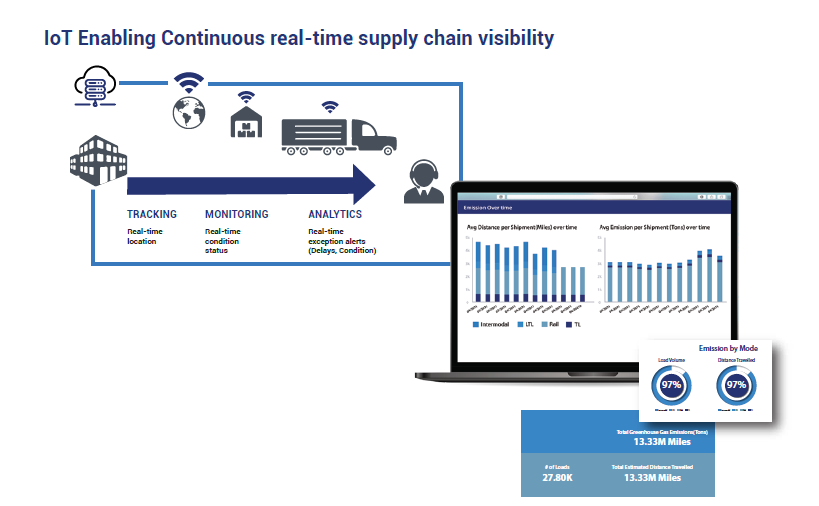

IoT monitoring devices riding along with the cargo can also help in gathering huge volumes of real-time data and analyzing emissions on a shipment level. Corporations can use the collected data to make key business decisions, reduce energy use and lower the carbon footprint of their supply chain.

Visibility at every supply stage

- Achieve visibility at every stage of the supply chain, from raw material till the finished product

Justify sustainability claims

- With tracing and end-to-end collaboration, product sustainability claims can be backed

Track carbon footprint

- IoT sensors track and analyze emissions at every stage

Case Study

Before: The challenge

Solution

By achieving lot level traceability of every material – across tiers and business units, the following was achieved

- Full visibility of material movements across the supply chain, enabling suppliers across three different continents to mimic the physical flow of materials as digital transactions on the platform.

- Successfully gained greater control of the movement of materials from one supplier to another, within the supplier facilities, as well as the records of the transformation of raw materials to final products – everything at a lot level.

- Successfully collected quality reports and transaction certificates for every lot – thus enabling higher confidence on the retailer’s sustainability claims.

After : The result

- Onboarded every supplier across 3 continents within the first 3 months.

- Was able to trace 30% of their units within the first 12 months of implementation.